Industrial automation is changing dramatically due to the advent of robotic arm. This has reshaped the world of manufacturing and production. Robotic arms, also known as Arm industrial robots are today indispensable tools that offer unparalleled precision, safety, and efficiency in a variety of industries. This article examines the capabilities of robot arms. They also discuss their impact on the modern business environment and the advancement in the field of industrial automation.

Robot arms are mechanical machines that can simulate the functions of human arms. They are more efficient and have a greater level of precision and endurance. These automated solutions find widespread applications in the automotive industry, manufacturing electronics assembly pharmaceuticals and many more, because of their ability perform complex, repetitive tasks with unprecedented accuracy. The robotic arms’ programming capabilities allow for seamless integration with diverse manufacturing settings. They also offer an incredibly wide range of motion and can adapt to varying needs.

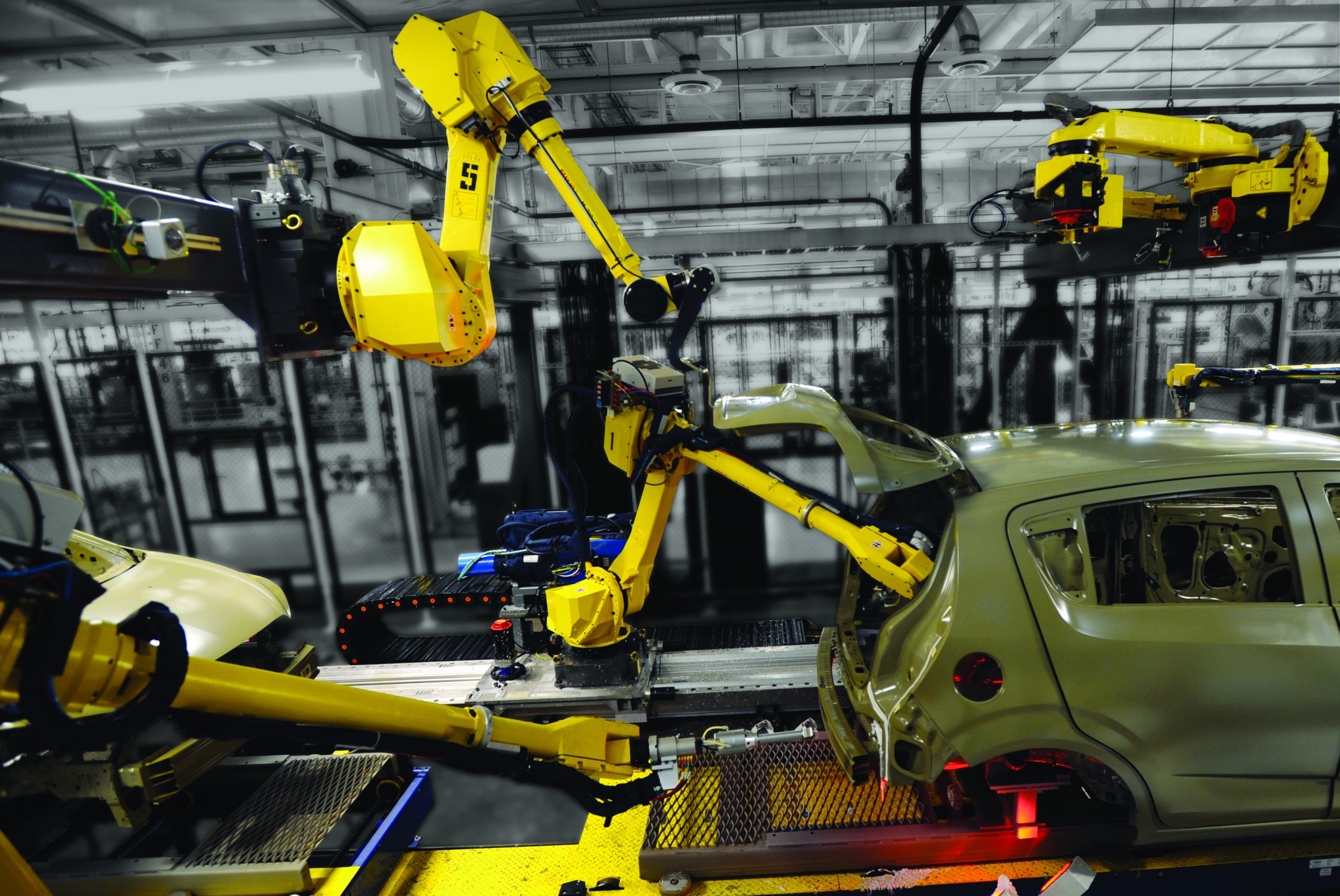

The robotic arm is the cornerstone of the modern age of automation. It represents a sophisticated sequence of articulations that can be moved, capable to rotate and perform linear displacements with exceptional dexterity. This allows robotic arms to maneuver through complicated spatial configurations manipulate objects with careful attention to detail and ensure optimal safety for human operators. Because of this, many companies have embraced robots as vital tools. This has simplified manufacturing processes and raised operational efficiency to unprecedented levels.

The use of end effectors by robot arms, which are the functional equivalent to hands, is one of the most distinct features of robotic arms. These end effectors, often designed to perform specific tasks, play an essential role in determining the scope of robotic arms’ applications. Robot hands with specialized end effectors can be used to accomplish a variety of tasks, from lifting and gripping large loads to securing complex parts.

In the contexts of industrial automation and robotic arms, an entire new era has been opened into productivity and innovations. Businesses can optimize their manufacturing processes through making use of the capabilities of robotic arms. They can also minimize human error and improve product quality. The seamless coordination between robotic arms and automation systems have resulted in significant efficiency improvements.

Robotic arms have a transformative effect that goes beyond automation. They are fundamentally changing the way that industrial processes are conducted. The integration and application of industrial robotics has improved the efficiency of existing manufacturing processes as well as paved way for completely new production techniques. Since they are able to work in dangerous or challenging environments, robot arms have increased safety in workplaces. They have also opened up new opportunities for complicated manufacturing processes.

Furthermore, the evolution of robotic arm technology has resulted in the development of innovative end effectors, specifically designed to meet particular industry requirements. These sophisticated end-effectors with cutting edge technology for grasping and sensory capabilities have expanded the scope for robotic arms. Companies can now address various manufacturing challenges with unimaginable flexibility and precision.

Australia’s embrace of robotic arm technology offers companies a chance to transform their business and improve their competitiveness and operational capabilities. Integrating robotic arms into industrial workflows can drive steady growth. It will also enhance overall efficiency. This will transform the way manufacturing processes are conducted. Robotic arms, designed with efficiency and precision in mind, will open new frontiers for industrial automation. Companies can reach unparalleled levels of efficiency and productivity.

Conclusion The integration of industrial robotic arms or robotic arms is a significant advancement in industrial automation. Robotic arms redefined the possibilities for modern manufacturing with their adaptability, accuracy, and security features. They provide businesses with an advantage in an increasing competitive market. The adoption of robotic arm technologies will benefit companies with improved productivity efficiency, efficiency, and ingenuity concepts.